Home > Mechanical Design

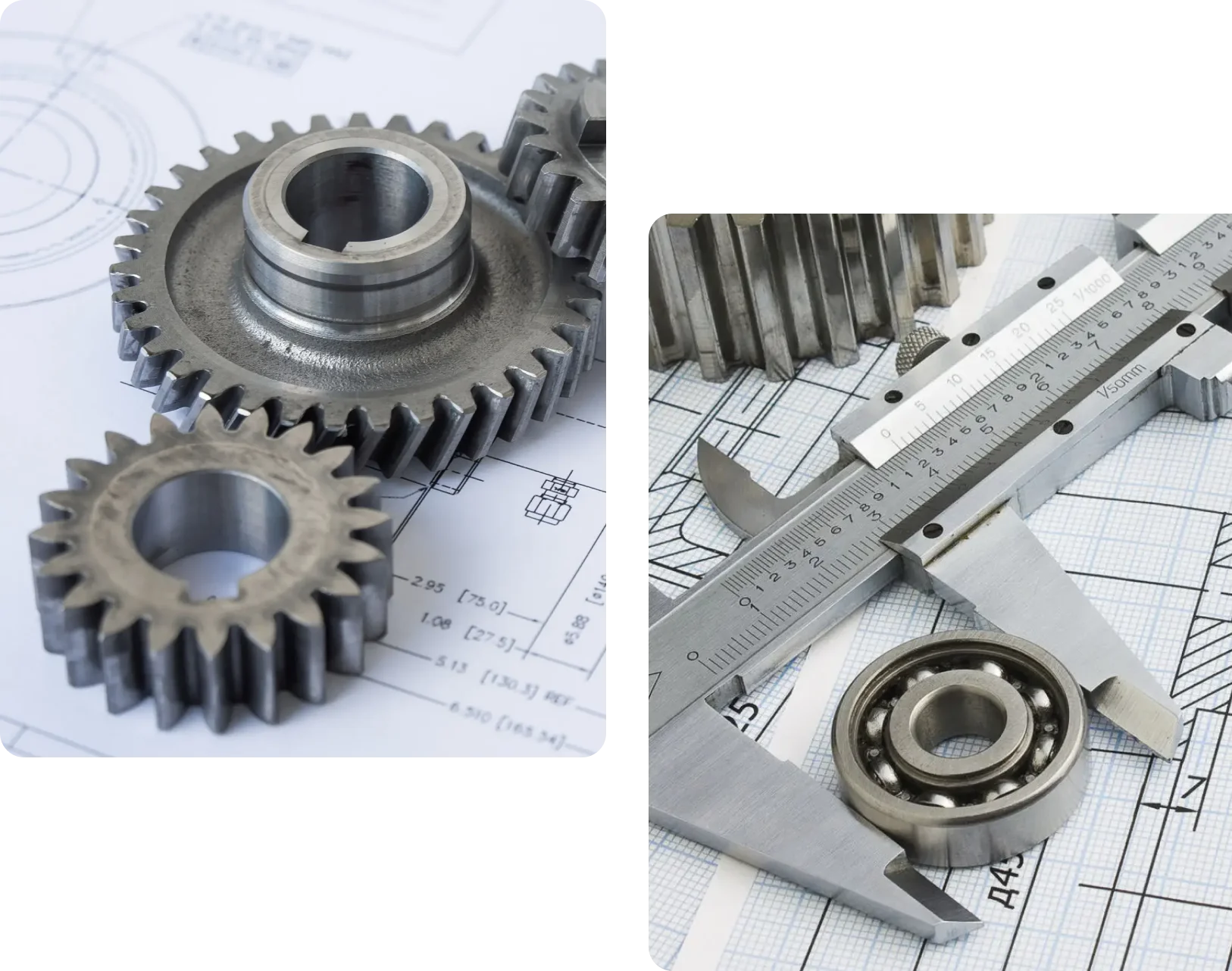

Mechanical design

EIPEKS uses the latest technology to customize mechanical design solutions for you. No matter what you need, we can provide high-quality and reliable support. Work with us to realize your ideas.

3D Printing Service

Welcome to our 3D Printing Service Center! Empower your creativity and add highlights to your projects with advanced 3D printing technology.

Mechanical Design Process

Step 1

Concept Generation

In the concept generation stage, we will start from these aspects to provide rich materials and diverse options for the preliminary design.

01

Members of the design team come together to brainstorm and come up with various concepts of mechanical structures and working principles.

02

Focus on product functionality, efficiency and reliability to ensure that design solutions cover diversity.

03

Deepen concepts and pool ideas and perspectives through team discussions and feedback.

Step 2

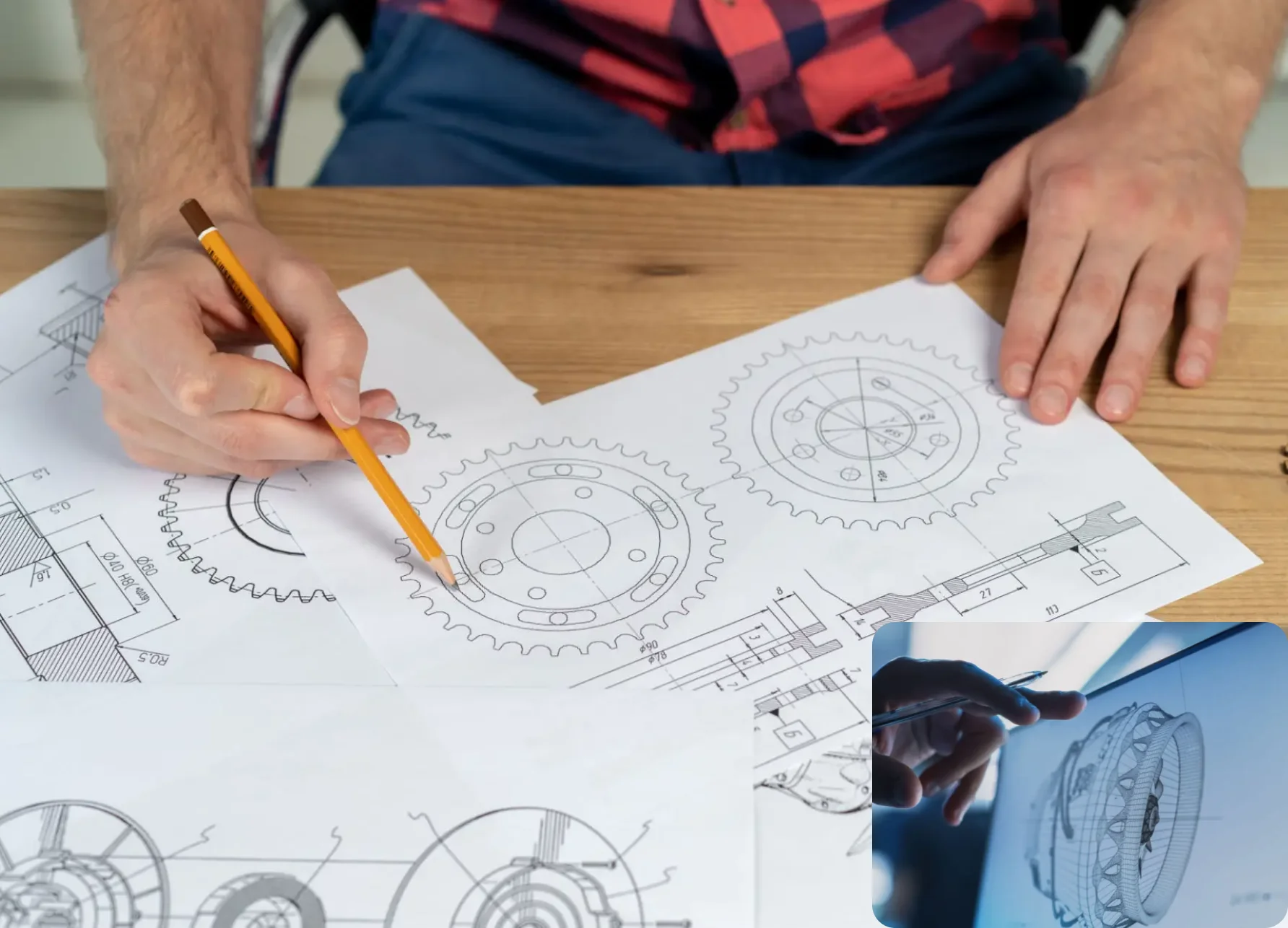

Preliminary Design

In the preliminary design stage, we will start from these aspects to turn abstract concepts into concrete objects, verify the feasibility of the concept, and provide clear directions for subsequent design and development.

01

After selecting some concepts, the design team turns them into preliminary sketches or graphical representations.

02

Use engineering software or hand-drawn sketches for structural design and component layout.

03

Carry out the preliminary basic calculation of strength, stiffness and so on to verify the feasibility of the design.

Step 3

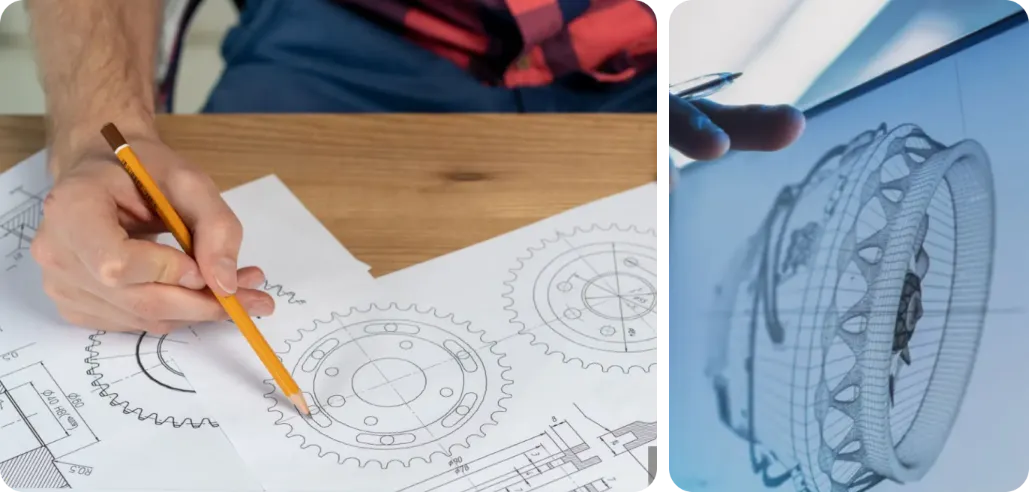

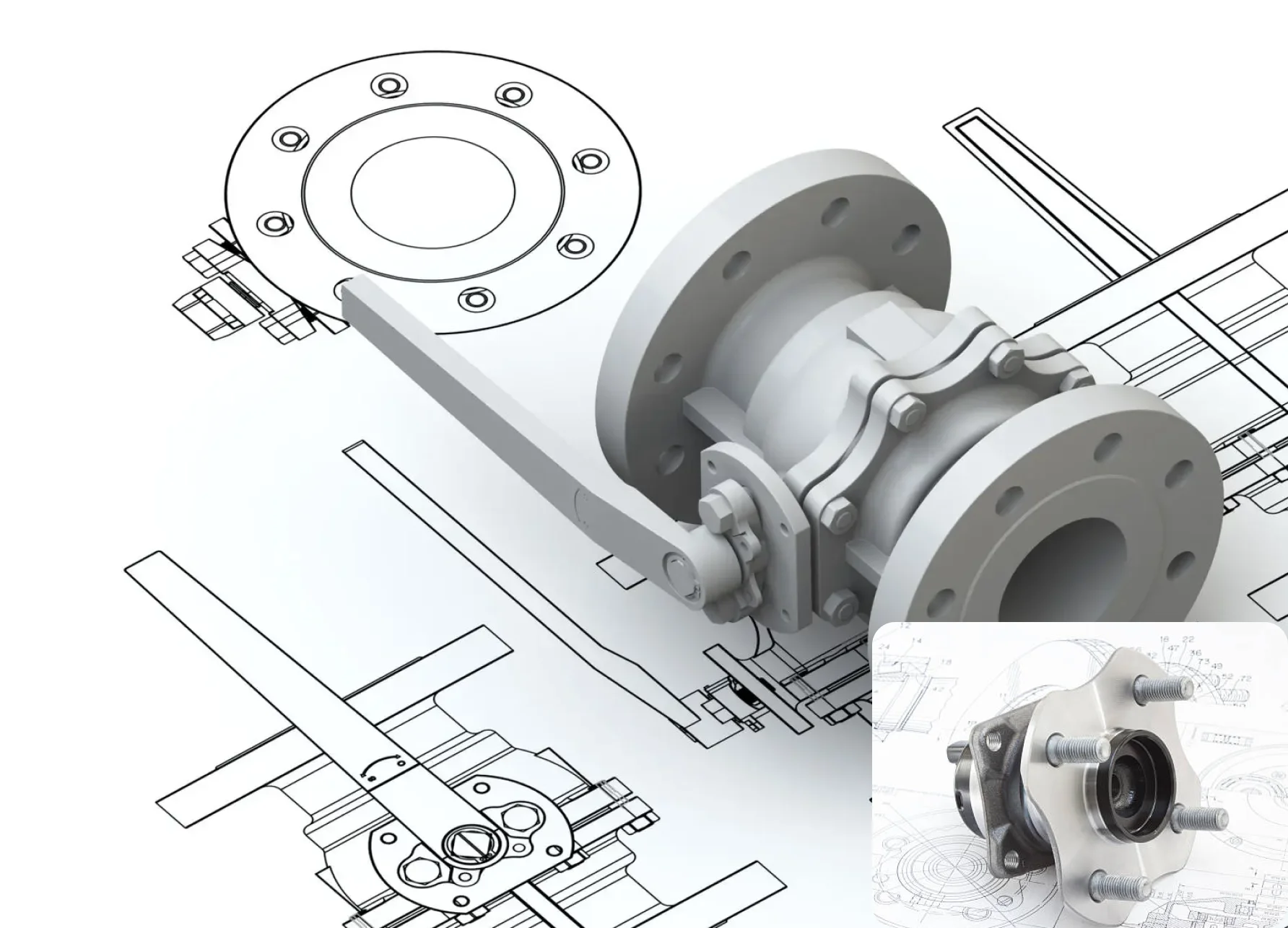

Detailed Design

The detailed design stage is the key to converting mechanical design into actual results, laying the foundation for the realization of the final product. We will start from the following aspects to improve the design details.

01

Use CAD software to create detailed 3D models, including precise dimensions and assembly relationships of components.

02

Add relevant parameters such as materials, processes, and surface treatments to improve design details.

03

Perform engineering analysis, such as finite element analysis, motion simulation, etc., to optimize the design scheme.

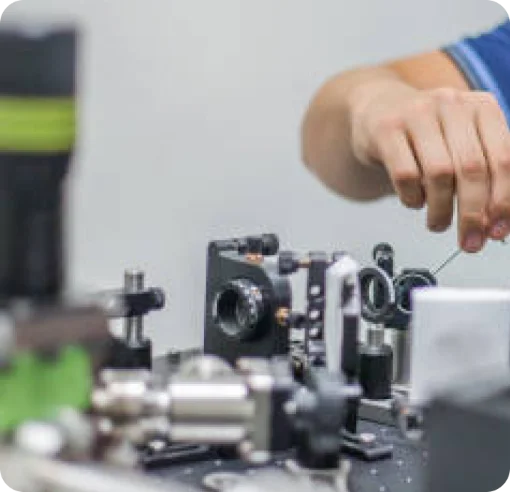

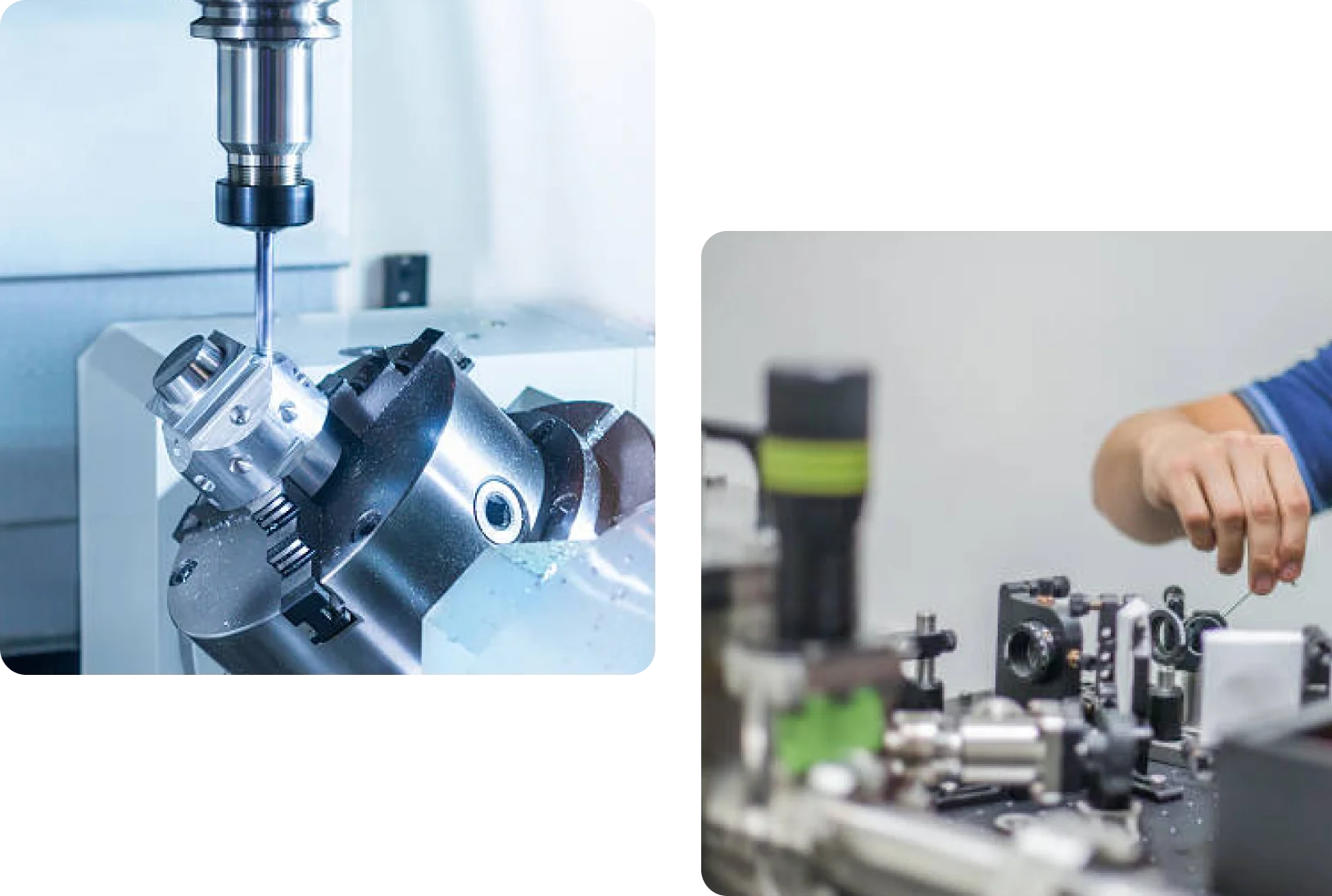

Step 4

Prototyping

During the prototyping stage, we will use the following two methods to ensure that the final product achieves the desired effect.

01

Make physical prototypes of mechanical products according to 3D models, which can be made by 3D printing, CNC machining and other methods.

02

Conduct functional testing and performance evaluation on prototypes, collect feedback and make necessary modifications.

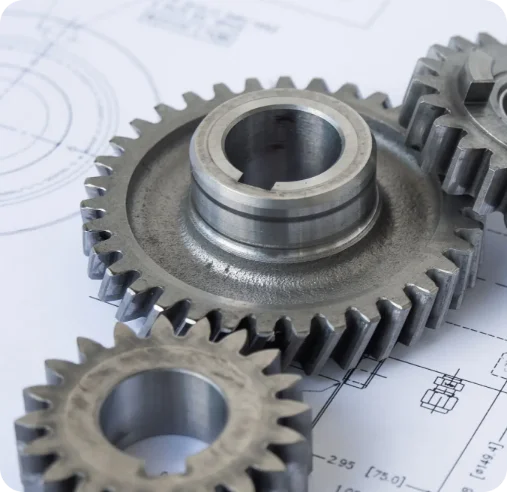

Common Manufacturing Processes of Mechanical Design

Whether you are an e-commerce brand, an offline independent brand or an emerging brand, we will tailor a satisfactory product strategy for you.

Casting Process

- Casting is a process where liquid metal or other materials are poured into a mold and allowed to cool and solidify to form the desired shape. Casting is suitable for producing large, complex-shaped parts such as engine blocks, wheels, etc.

Forging Process

- Forging is the process of deforming a metal material into a desired shape by applying pressure to it. The forging process is suitable for producing high-strength, high-precision parts, such as crankshafts, connecting rods, etc.

CNC Machining

- CNC machining is a process that uses CNC machine tools to perform cutting, milling, turning, etc. on workpieces. CNC machining has the characteristics of high precision, high efficiency and flexibility, and is suitable for producing precision parts and small batch production.

Injection Molding

- Injection molding is a process in which molten plastic or other thermoplastic materials are injected into a mold and formed into the desired shape after cooling and solidification. The injection molding process is suitable for producing large quantities of plastic parts with complex shapes.

Professional Knowledge

Engineering Mechanics

Engineering mechanics forms the foundation of mechanical design, involving concepts such as force, torque, stress, strain and so on. It contains statics (balance of forces), dynamics (the study of motion), and materials mechanics (the strength and stiffness of materials).

Materials Science & Engineering

Understand the characteristics, performance and application range of different materials such as metal materials, plastics, composite materials, etc., to select the most appropriate materials to manufacture parts and systems.

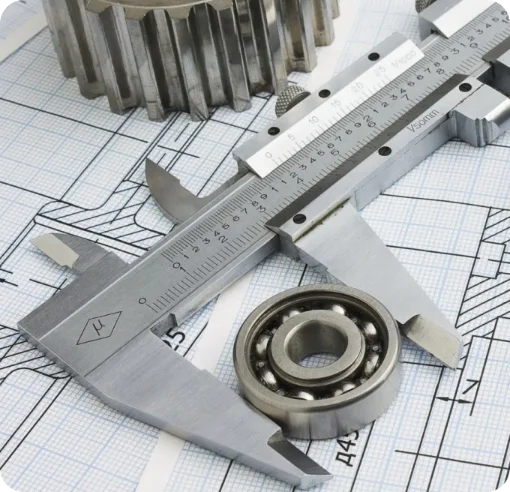

Mechanical Design Principle

Mechanical design principle covers the basic principle and method of mechanical design, including important contents such as mechanism design, gear design, bearing design, and transmission design.

Surface Engineering Technology

Surface engineering technology involves modifying the surface of materials to improve their surface hardness, wear resistance, corrosion resistance and other properties. This includes technologies such as thermal treatment, electrochemical treatment, surface coating and spraying.

Read part cases of our customers.

Product List

EIPEKS has successfully created 1000+ best-selling products. Contact us for more information.

Portable Home Gym

Intelligent Category

Cycling Helmet

Structural Category

Bicycle Electrifcation Kit

Intelligent Category

Dual-Camera Drone

Intelligent Category

Rehabilitation Glove

Intelligent Category

Quantum Smart Headphone

Intelligent Category

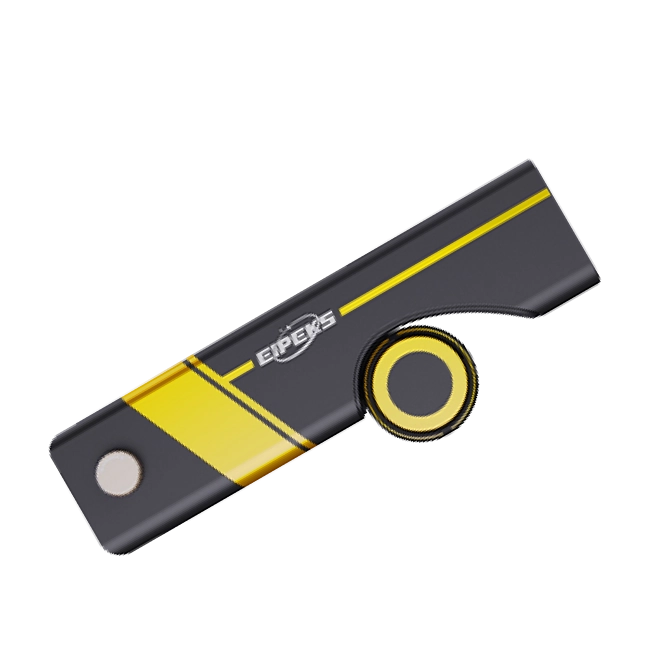

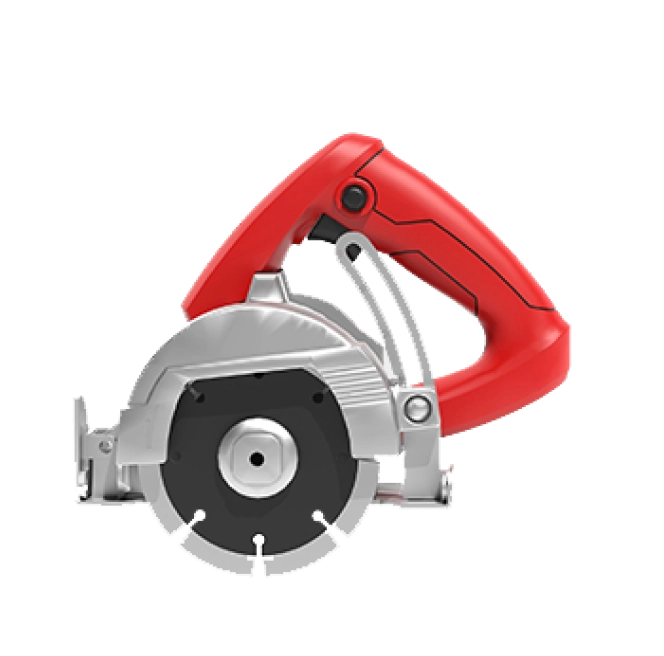

Cutting Machine

Structural Category

Compiles selected product cases from over 1000 successful projects by EIPEKS, with each case disclosed with the client’s authorized consent.

Are You Ready To Star Your Industrial Design Project?

FAQ

- What is mechanical design?

Mechanical design is an engineering discipline that involves the process of designing, analyzing, and manufacturing mechanical systems, equipment, and parts. Mechanical designers use engineering knowledge and skills to create a wide variety of mechanical products to meet the needs of different industries and applications.

- How to select materials in mechanical design?

Choose the most appropriate material based on factors such as the product’s use environment, load conditions, cost, and manufacturing process. Common selection criteria include material strength, hardness, wear resistance, corrosion resistance, and cost.

- How to choose a suitable manufacturing process?

Selecting a suitable manufacturing process requires consideration of multiple factors, including product geometry, material properties, throughput, cost and time. Comprehensive analysis and evaluation are often required to find the most suitable process.

- Why is engineering mechanics analysis needed in mechanical design?

Engineering mechanics analysis helps mechanical designers understand the force conditions and structural characteristics of products to ensure the safety, stability and reliability of products under various working conditions.

Anhui

Anhui

Headquarter

Headquarter

D1 Building, Gongtou Liheng Industrial Plaza, Fanhua Avenue, Feixi County, Hefei City, Anhui Province, China

Shenzhen

Shenzhen

E-Commerce Marketing Research Center

E-Commerce Marketing Research Center

Sanding E-Commerce Building, Bantian Street, Longgang District, Shenzhen, Guangdong, China

Hangzhou

Hangzhou

Product R&D Center

Product R&D Center

A210, Zone A, Dongxi Derbiyi Park, Dongning Road, Shangcheng District, Hangzhou, Zhejiang, China

Beijing

Beijing

Hardware and Software Technology and Testing Center

Hardware and Software Technology and Testing Center

No. 536 Huaisha Road, Bohai Town, Huairou District, Beijing, China

Hongkong

Hongkong

Hong Kong Office

Hong Kong Office

RM 21 UNIT A 11/F TIN WUI IND BLDG NO 3 HING WONG ST TUEN, MUN, NT, HK